To take advantage of the global expertise of the leaders in foundry technologies, we held an event to present the technological advances in the foundry world, bringing together the country's main foundry players and users.

To take advantage of the global expertise of the leaders in foundry technologies, we held an event to present the technological advances in the foundry world, bringing together the country's main foundry players and users.

En Quipasur, valoramos profundamente las relaciones de largo plazo con nuestros clientes. Un ejemplo de esto es Fundición Las Rosas, quien ha confiado en nuestra experiencia y soluciones para el rubro industrial.

To take advantage of the global expertise of the leaders in foundry technologies, we held an event to present the technological advances in the foundry world, bringing together the country's main foundry players and users.

Durante nuestra visita, colaboramos con diversas fundiciones líderes en el Perú, como Funvesa, Fucsa, Mepsa, Fundición Ferrosa y Funespa, entre otras.

Durante esta experiencia, pudimos observar de cerca el uso de productos esenciales para la fundición, como mangas exotérmicas, resinas, catalizadores y más. Nos complace informar que los gerentes y técnicos de estas fundiciones mostraron un gran interés en nuestras soluciones para mejorar la calidad de las piezas fundidas.

Agradecemos sinceramente a C&T Representaciones por su apoyo y confianza, así como a las fundiciones peruanas por su hospitalidad y profesionalismo durante nuestra visita. Nos comprometemos a continuar fortaleciendo nuestra alianza con nuestros distribuidores y clientes peruanos, ofreciendo nuestro apoyo técnico y comercial.

We are pleased to formally announce to the Peruvian market our commercial relationship with CyT Representations, a leader in the foundry industry in Peru. This alliance represents a solid commitment to drive innovation and excellence in a sector that is growing rapidly.

It is a testament to the trust and respect we have built over the years and a recognition of the importance of joining forces to meet the challenges and seize the opportunities that lie ahead in the foundry area.

We thank all those who have made this union possible. We are sure that this is the first step towards a promising and successful future.

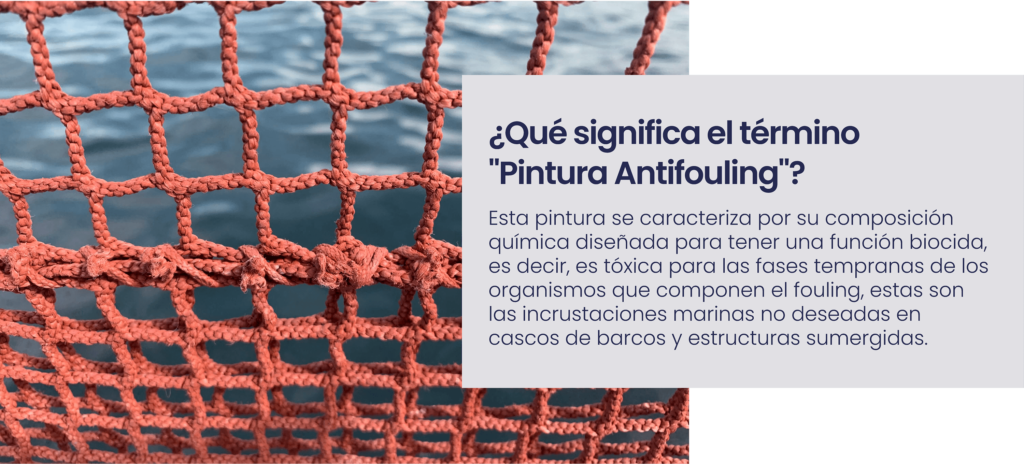

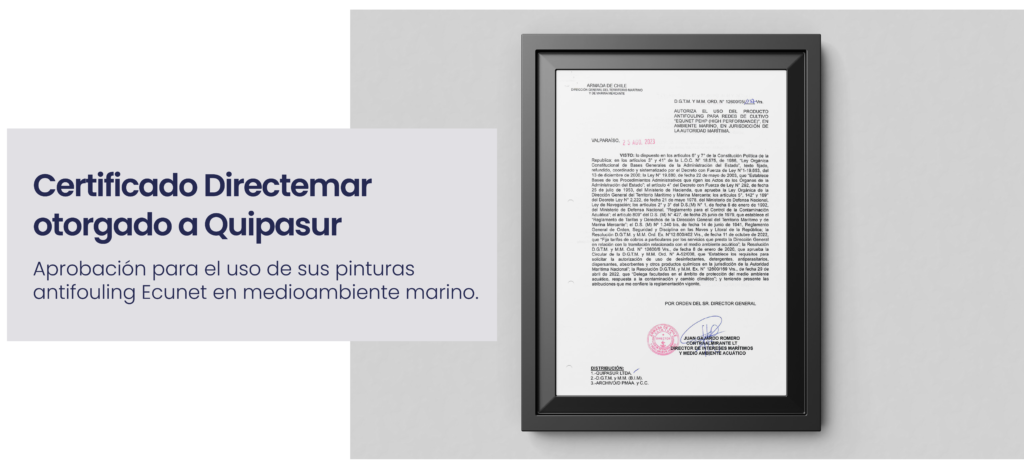

Currently, obtaining Directemar certification for disinfectants, detergents, antiparasitics, dispersants, absorbents and other chemical products (fungicides, preservatives, among others) has become a fundamental requirement for any company wishing to market these products.

Failure to obtain this certification can lead to significant penalties, which makes it an unavoidable standard for the industry. However, beyond regulations and fines, this certification is a commitment to the environment and the preservation of the marine ecosystem, an imperative demand from the salmon industry and a "duty" towards the sustainability of our oceans.

The main objective of this certification is to ensure that the products comply with the necessary requirements to request authorization for use under the jurisdiction of the National Maritime Authority. The Maritime Authority has the important task of monitoring and ensuring compliance with international conventions and legal regulations related to the preservation of the marine ecosystem.

It is important to note that docks, maritime facilities, fixed or floating platforms and naval artifacts, in general, require the use of chemical products for the maintenance and conservation of their structures, and all these products must comply with established standards.

Companies that achieve this certification have undergone a rigorous process of evaluation of their products, a process which, if successful, confirms that they are suitable for use in the marine environment.

The review process consists of the inspection of ecological and chemical risks. In order to obtain certification, it is necessary to provide a series of essential data, including:

Obtaining Directemar certification is not only a legal obligation, but a commitment to sustainability and the protection of the marine environment. It helps to ensure that our oceans remain healthy and free of pollutants harmful to marine life and, ultimately, to the ecological balance of our planet.

The Quipasur delegation, headed by Ricardo Hermosilla, Foundry Manager, Marco Salazar, Development Manager, Fernando Baltra, Director and Raúl Silva, General Manager, was present during the event, sharing with international suppliers and customers.

Quipasur's visit to the GIFA Fair was highly fruitful, fulfilling all the expectations established in terms of establishing new contacts, exploring new technologies and generating contact with international suppliers. In addition, they had the opportunity to meet with two of their main clients, thus strengthening their business relationship.

During the fair, Quipasur was pleased to find new international suppliers of products, raw materials and machinery. The main objective of the acquisition of state-of-the-art machinery is the modernization of processes. These machines offer greater productivity and speed, which will improve costs, strengthen production control and achieve absolute homogeneity in the production line. This investment is made in order to maintain quality and remain at the forefront of the market, in a constant effort to keep up to date with the latest technology and continuously improve production processes without lowering quality standards.

Quipasur's participation in the fair provided a valuable opportunity to expand its network of contacts, acquire knowledge about new technologies and reaffirm its commitment to excellence in the foundry industry. Meetings were also held with Quipasur's distributor in Peru (CyT), with whom a strategic alliance was signed for the Peruvian market.

Quipasur, being aligned with global requirements and the demands of its customers, has established strategic alliances with international suppliers and partners, seeking to generate new contacts and resume business relationships to expand its product offering and add new products to its catalog. Quipasur has also consolidated its relationship with ASK, a company that also participated in the fair and with which it shares a range of manufactured products. Through these actions, Quipasur positions itself as a competitive and constantly evolving company, ready to meet the needs of the global market.

In the process, several aspects were analyzed, including the quality of the material or service provided by Quipasur, compliance with deadlines and delivery quantities, as well as its performance in terms of health, occupational safety and the environment.

Quipasur stood out as an outstanding supplier of foundry supplies and products, obtaining the highest "A" rating, being qualified as a reliable supplier in each area mentioned, demonstrating an outstanding quality in the products or services supplied, as well as a high level of compliance with the agreed deadlines and quantities. In addition, the company distinguished itself for its commitment to the health and safety of its workers and care for the environment.

The high valuation of Quipasur as a key supplier highlights Quipasur's dedication, excellence and constant commitment to provide high quality solutions and meet the needs of its customers. This recognition reinforces Quipasur's positioning as a reliable company and establishes our position as leading experts in chemical solutions for the country's most important industries.

Nitracomp 25® is a liquid fertilizer that provides a concentrated and soluble solution of modified amino methylene ureas. This product is the result of stable chemical reactions between concentrated urea and methylformadehyde, which produces a completely water soluble resin. One of the outstanding features of Nitracomp 25 is its ability to immediately release and assimilate 70% of the available nitrogen, while the remaining 30% acts as a controlled release with a long lasting effect, which can be extended between 3 to 4 weeks.

This fertilizer is specially formulated to promote vegetative development during growth stages that demand a high and prolonged supply of nitrogen. One of the benefits of foliar nitrogen is the plant's energy savings, since it avoids the process of absorption and transport of nutrients from the soil to the foliage. This means that the plant's energy consumption (derived from starches and proteins) is reduced.

The technical characteristics of Nitracomp 25 include the formation of long polymeric chains based on nitrogen and heterocycles during the manufacturing process of the product. These chains take longer to decompose, which provides the effect of slow nitrogen release. In addition, this fertilizer contributes to reducing leaching, volatilization and fixation losses, thus avoiding contamination of groundwater. It is also characterized by having a low Biuret content and does not generate toxicity symptoms in plants when the doses recommended by the agricultural advisor are used.

Another advantage of Nitracomp 25 is its adherent presentation, which allows an excellent retention capacity on the foliage. The film that forms on the leaves releases nitrogen slowly, through compounds such as N-methylene urea and triazones present in the long polymeric chains, allowing a gradual absorption. In addition, this fertilizer contains a rapidly absorbed nitrogen fraction in the form of urea.

Ferosor distributes Quipasur's Nitracomp 25 liquid fertilizer, and in the past month has carried out a field evaluation to demonstrate the effectiveness of Nitracomp and to show the technology developed by Quipasur in southern Chile. The main objective of these activities is to promote the efficient use of fertilizers in southern Chile.

Quipasur and Ferrosor have carried out various development and training activities in cities such as Loncoche, Los Lagos, Río Bueno, Osorno, Purranco and Puerto Varas. These activities have been led by Gerardo Ramírez, a consultant in pastoral production systems.

The talk was aimed at raising awareness and prevention of drunk driving and responsible behavior in public spaces, which was a very enriching experience for all attendees.

During the talk, Emilia's father spoke about the importance of taking preventive measures to avoid traffic accidents caused by drunk drivers. He shared his personal experience and explained how the tragedy of his daughter's death inspired him to work to raise awareness about the dangers of drunk driving.

Fundación Emilia's talk at Quipasur is just a sample of the commitment to support its employees in different roles in their lives, including the family and responsibility as citizens in public spaces. Seeking at all times that, as people, members of a company and participants of this society, we find constant growth.

More information about the foundation at https://www.fundacionemilia.cl/

Recent comments